Fully funded 45,000 m program positions Mithril for catalyst-rich year ahead

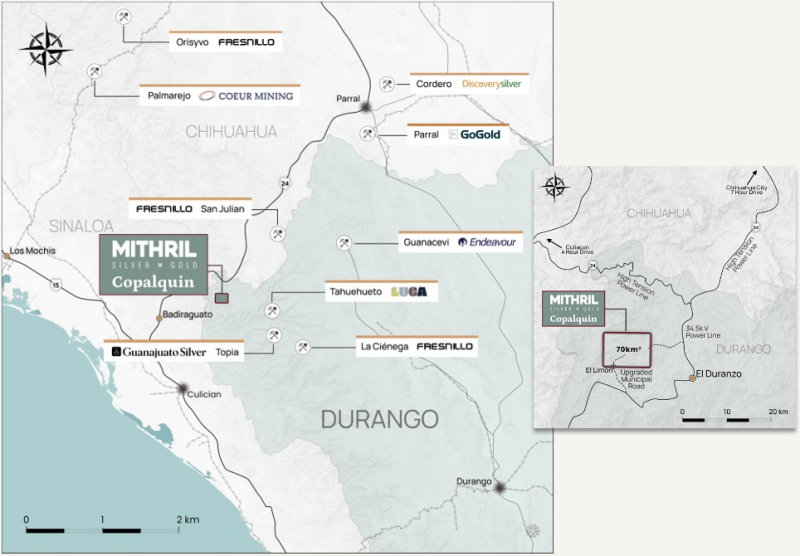

Melbourne, Australia and Vancouver, Canada – TheNewswire - August 28, 2025 - Mithril Silver and Gold Limited ("Mithril” or the "Company") (TSXV: MSG) (ASX: MTH) (OTCQB: MTIRF) is pleased to provide exploration results for multiple targets at Mithril’s district scale Copalquin property, Durango State, Mexico.

District Outlook

Mithril is fully funded to complete 45,000 m of drilling over the next 12–14 months, with preparations to add a third drill rig in early 2026. Exploration, including drilling and detailed mapping, continues to advance across multiple targets, underpinning the district-scale potential of Copalquin. A closely-spaced aeromagnatic survey is planned for Q4 2025 after the wet season.

Target 5 – Apomal Historic Mine

Drilling has commenced at the Apomal historic mine in the Target 5 area, with the first three holes completed in an initial 5,000 metre program. Apomal is being tested down dip, below the old workings and along strike. This program marks the first drilling at the target and is designed to test the mapped veins while stepping out into untested areas along strike and at depth. Target 5 has so far been traced on surface for over 1.2km along strike of the vein system, and some 1.5km across the strike of the system.

Target 1 – Objective to Expand High-Grade Footprint Ahead of Target 1 Resource Update

-

La Soledad (East): Drilling continues to return strong high-grade intercepts, including 3.30 m @ 8.63 g/t gold, 41.2 g/t silver (MTH-LS25-36), with 0.50 m @ 48.85 g/t gold and 91.55 g/t silver

-

Zaragoza (South): The first drill hole at this new area, located 500 m southeast of Refugio, returned 0.57 m @ 6.80 g/t gold and 4,400 g/t silver at the projected target depth (MTH-ZG25-37). The intercept lies ~160 m below historic workings, confirming depth potential and opening a new high-grade zone along strike toward the historic Copalquin Mine 900 metres south east of Refugio. The entire strike length of approximately 1,400 metres is now considered to be a target.

-

Refugio West: Step-out drilling is in progress 250 metres west of the maiden resource area, targeting extensions along the east-west structure toward El Gallo, a further 900 metres to the west.

Target 3 – Preparing for 2025 Drilling

Systematic mapping and sampling at Target 3 continues to define targets in this extensive area ahead of its maiden drill program in the coming months.

“Our exploration program continues to advance across the district, expanding the Target 1 resource area, drilling new zones and develping additional targets through systematic mapping and sampling,” commented John Skeet, Managing Director & CEO. “The Team’s efforts are consistently delivering excellent results, accelerating the geologic modelling of this large epithermal gold-silver system.

First-pass drilling at Zaragoza, 500 metres southeast of Refugio, has confirmed extensions of high-grade mineralization to depth, with notably higher silver grades relative to gold. Mineralisation is now demonstrated 160 metres down-dip into the granodiorite intrusive, underscoring the potential scale and vertical continuity of this system. Drilling at Target 5 commenced on schedule, with the first three holes already complete and assays pending.”

COPALQUIN GOLD-SILVER DISTRICT, DURANGO STATE, MEXICO

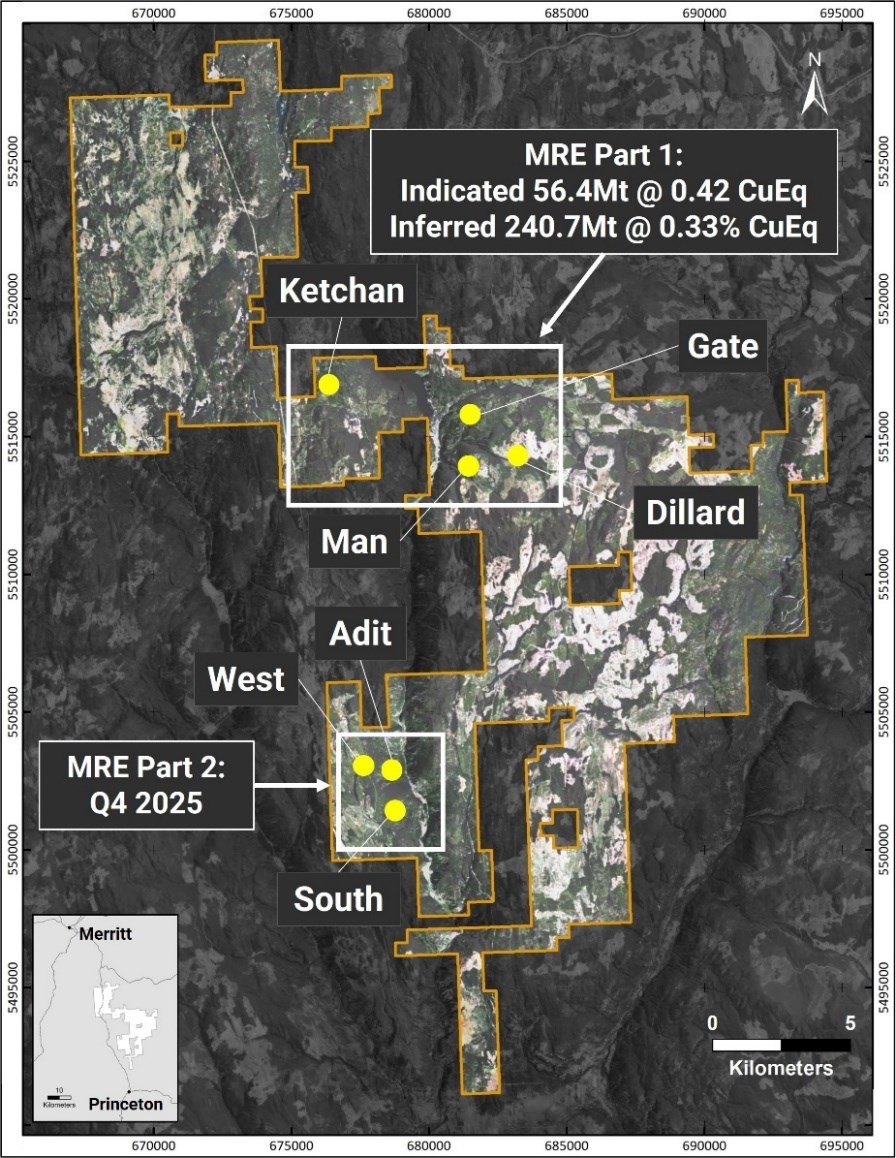

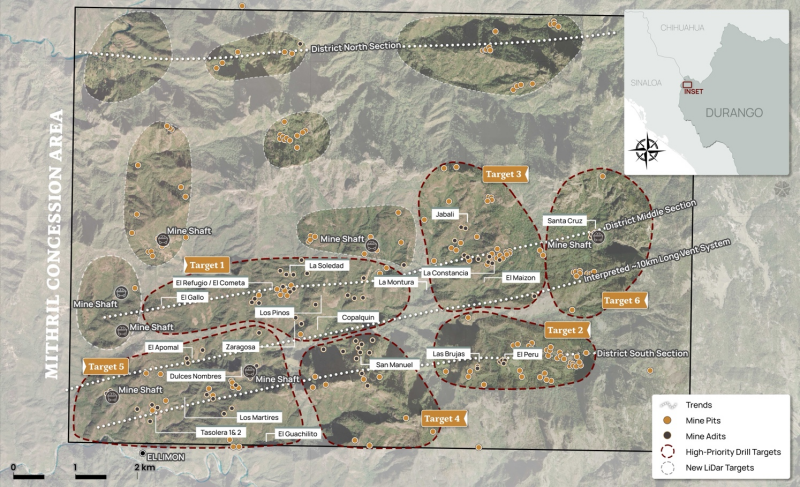

Figure 1 – Copalquin District location map, locations of mining and exploration activity and local infrastructure.

Figure 1 – Copalquin District location map, locations of mining and exploration activity and local infrastructure.

With 100 historic underground gold-silver mines and workings plus 198 surface workings/pits throughout 70km2 of mining concession area, Copalquin is an entire mining district with high-grade exploration results and a maiden JORC resource. To date there are several target areas in the district with one already hosting a high-grade gold-silver JORC mineral resource estimate (MRE) at the Target 1 area (El Refugio-La Soledad)1 and a NI 43-101 Technical Report filed on SEDAR+, supported by a conceptional underground mining study completed on the maiden resource in early 2022 and metallurgical test work (see ASX Announcement 25 February 2022). There is considerable strike and depth potential to increase the resource at El Refugio and at other target areas across the district, plus the underlying geologic system that is responsible for the widespread gold-silver mineralisation.

With the district-wide gold and silver occurrences and rapid exploration success, it is clear the Copalquin District is developing into another significant gold-silver district like the many other districts in this prolific Sierra Madre Gold-Silver Trend of Mexico.

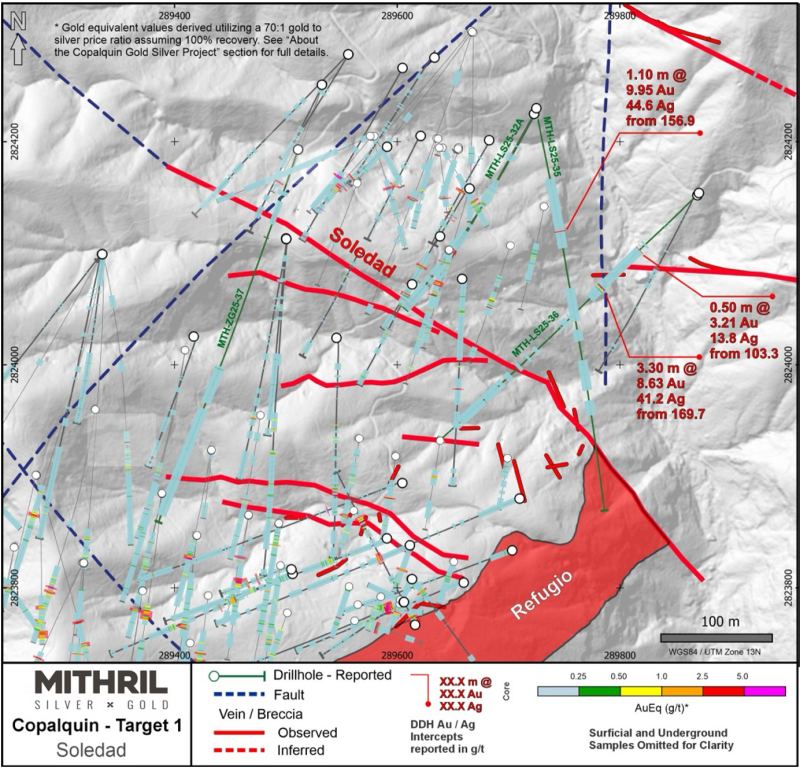

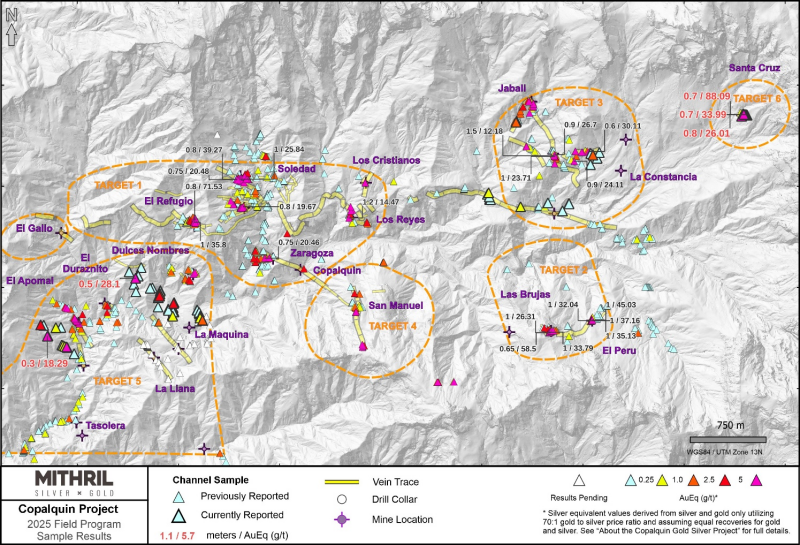

Figure 2 LiDAR identified historic workings across the 70km2 district. Current drilling locations at Target 1 west and Target 5 (El Apomal), and recent drilling at Zaragoza mine in Target 1 south, high priority drill target area of La Constancia-El Jabali (Target 3). Several new areas highlighted across the district for follow-up work including recently sampled Target 6

Figure 2 LiDAR identified historic workings across the 70km2 district. Current drilling locations at Target 1 west and Target 5 (El Apomal), and recent drilling at Zaragoza mine in Target 1 south, high priority drill target area of La Constancia-El Jabali (Target 3). Several new areas highlighted across the district for follow-up work including recently sampled Target 6

Copalquin District Exploration Progress Update

Drill Results Discussion

Exploration Progress Update

Drilling at La Soledad, the NW trending structure on the eastern side of Target 1, has produced further excellent results with the highlight drill holes MTH-LS25-35 and MTH-LS25-36. These holes confirm mineralisation down dip from the existing block model, and that mineralisation is still open at depth.

-

MTH-LS25-35 1.1m @ 9.95 g/t gold, 44.6 g/t silver from 156.9m

-

MTH-LS25-36 0.5 m @ 3.21 g/t gold, 13.8 g/t silver from 103.3 m

-

MTH-LS25-36 3.3 m @ 8.63 g/t gold, 41.24 g/t silver from 169.7 m, including

0.5 m @ 48.85* g/t gold, 91.55* g/t silver from 169.7 m

*Values were averaged from duplicate samples

Table 1 Summary of drill intercepts drilling at Target 1, La Soledad.

|

Drill Hole ID |

From (m) |

To (m) |

Interval (m) |

Au g/t |

Ag g/t |

Au Eq g/t |

|

MTH-LS25-35 |

156.90 |

158.00 |

1.1 |

9.95 |

44.6 |

10.59 |

|

MTH-LS25-36 |

103.3 |

103.8 |

0.5 |

3.21 |

13.8 |

3.41 |

|

MTH-LS25-36 |

169.7 |

173 |

3.3 |

8.63 |

41.24 |

9.21 |

|

Including |

169.7 |

170.2 |

0.5 |

48.85 |

91.55 |

50.16 |

Figure 3 Plan map showing drill traces and results of ongoing drilling at La Soledad in Target 1 area

Figure 3 Plan map showing drill traces and results of ongoing drilling at La Soledad in Target 1 area

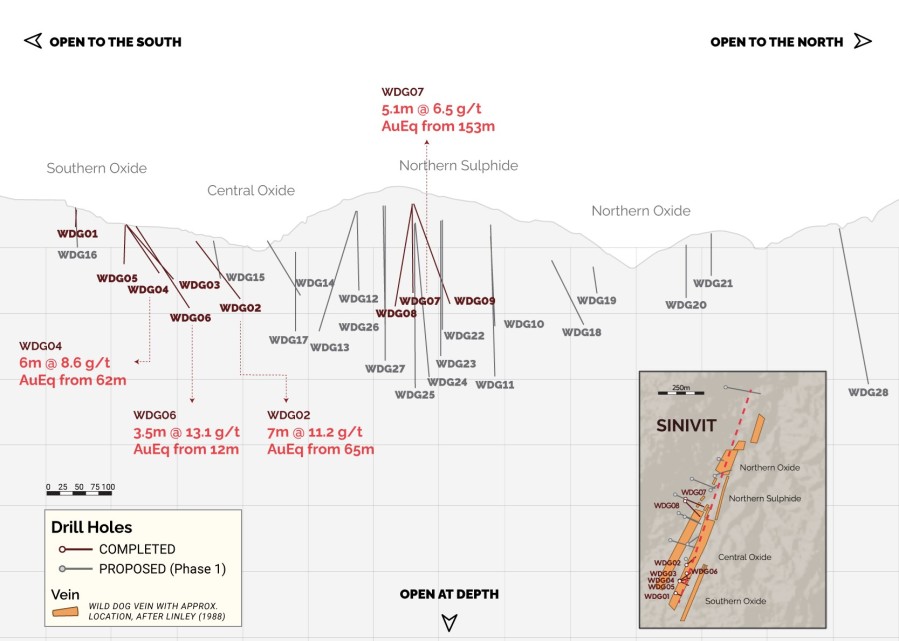

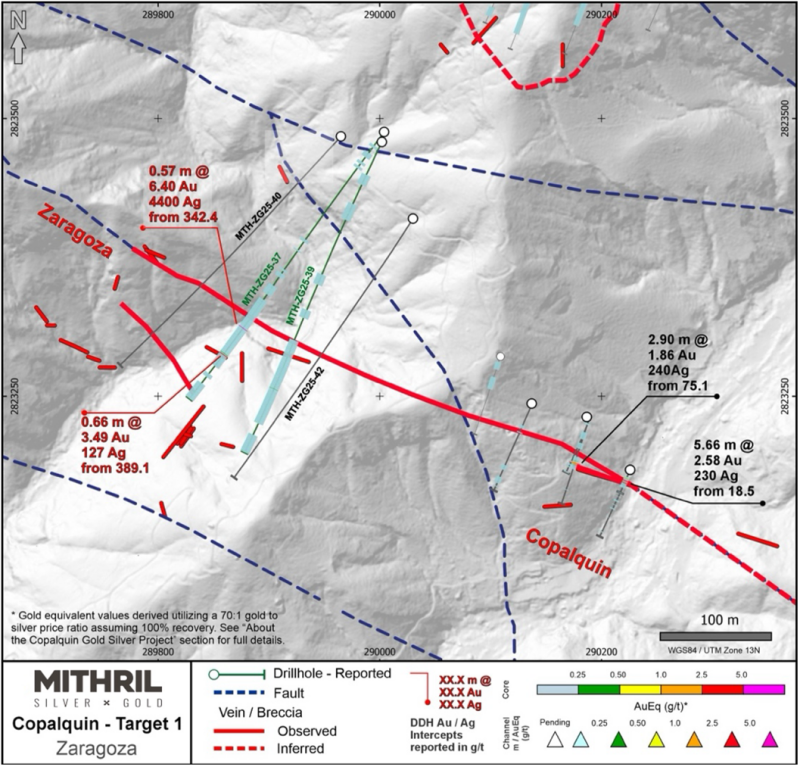

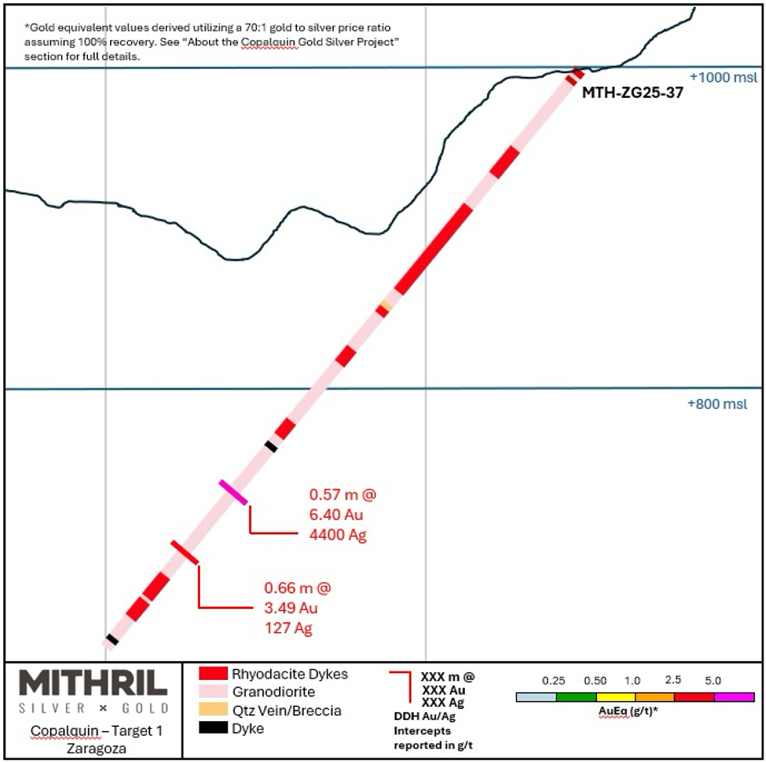

First Drilling at Zaragoza, located 500 metres from the Refugio resource area (see Figure 6), has yielded excellent results. Four holes have been completed over a 200 metre strike length. Drill hole MTH-ZG25-37 intersected significant gold and silver within two separate, broad structures returning:

-

MTH-ZG25-37 0.57 m @ 6.4 g/t gold, 4400 g/t silver from 342.4 m

-

MTH-ZG25-37 0.66 m @ 3.49 g/t gold, 127 g/t silver from 389.1 m

Table 2 Summary of drill intercepts at Target 1, Zaragoza

|

Drill Hole ID |

From (m) |

To (m) |

Interval (m) |

Au g/t |

Ag g/t |

Ag Eq g/t |

|

MTH-ZG25-37 |

342.4 |

342.97 |

0.57 |

6.4 |

4,400 |

4,848 |

|

MTH-ZG25-37 |

389.1 |

389.76 |

0.66 |

3.49 |

127 |

371.3 |

Figure 4 Plan view showing reported drill traces and pending drill hole traces at Zaragoza, within the Target 1 area

Figure 4 Plan view showing reported drill traces and pending drill hole traces at Zaragoza, within the Target 1 area

Drilling at Target 5 has commenced, focusing on numerous north west-trending vein systems, including those at the historic Apomal Mine. To date, three drill holes have been successfully completed, and early indications from the program have delivered encouraging results, which, coupled with the widespread high grade surface samples, support the potential for a significant area of mineralization in this highly prospective zone.

Figure 5 Cross section for first drill hole at Zaragoza MTH-ZG25-37

Figure 5 Cross section for first drill hole at Zaragoza MTH-ZG25-37

Figure 6 Property-wide channel sampling results for the middle and south district sections within ~50% of the 70 km2 mining concession area covering the Copalquin District (see July 29, 2025 announcement, High-Grade Channel Sample Results)

Figure 6 Property-wide channel sampling results for the middle and south district sections within ~50% of the 70 km2 mining concession area covering the Copalquin District (see July 29, 2025 announcement, High-Grade Channel Sample Results)

ABOUT THE COPALQUIN GOLD SILVER PROJECT

The Copalquin mining district is located in Durango State, Mexico and covers an entire mining district of 70km2 containing several dozen historic gold and silver mines and workings, ten of which had notable production. The district is within the Sierra Madre Gold Silver Trend which extends north-south along the western side of Mexico and hosts many gold and silver districts.

Multiple mineralisation events, young intrusives thought to be system-driving heat sources, widespread alteration together with extensive surface vein exposures and dozens of historic mine workings, identify the Copalquin mining district as a major epithermal centre for Gold and Silver.

Within 15 months of drilling in the Copalquin District, Mithril delivered a maiden JORC mineral resource estimate demonstrating the high-grade gold and silver resource potential for the district. This maiden resource is detailed below (see ASX release 17 November 2021)^ and a NI 43-101 Technical Report filed on SEDAR+

-

Indicated 691 kt @5.43 g/t gold, 114 g/t silver for 121,000 oz gold plus 2,538,000 oz silver

-

Inferred 1,725 kt @4.55 g/t gold, 152 g/t silver for 252,000 oz gold plus 8,414,000 oz silver

(using a cut-off grade of 2.0 g/t AuEq*)

-

28.6% of the resource tonnage is classified as indicated

Table 3 Mineral resource estimate El Refugio – La Soledad using a cut-off grade of 2.0 g/t AuEq*

|

Tonnes (kt) |

Tonnes |

Gold |

Silver |

Gold Eq.* (g/t) |

Gold |

Silver |

Gold Eq.* (koz) |

|

|

El Refugio |

Indicated |

691 |

5.43 |

114.2 |

7.06 |

121 |

2,538 |

157 |

|

Inferred |

1,447 |

4.63 |

137.1 |

6.59 |

215 |

6,377 |

307 |

|

|

La Soledad |

Indicated |

- |

- |

- |

- |

- |

- |

- |

|

Inferred |

278 |

4.12 |

228.2 |

7.38 |

37 |

2,037 |

66 |

|

|

Total |

Indicated |

691 |

5.43 |

114.2 |

7.06 |

121 |

2,538 |

157 |

|

Inferred |

1,725 |

4.55 |

151.7 |

6.72 |

252 |

8,414 |

372 |

* In determining the gold equivalent (AuEq.) grade for reporting, a gold:silver price ratio of 70:1 was determined, using the formula: AuEq grade = Au grade + ((Ag grade/70) x (Ag recovery/Au recovery)). The metal prices used to determine the 70:1 ratio are the cumulative average prices for 2021: gold USD1,798.34 and silver: USD25.32 (actual is 71:1) from kitco.com. At this early stage, the metallurgical recoveries were assumed to be equal (93%). Subsequent preliminary metallurgical test work produced recoveries of 91% for silver and 96% for gold (ASX Announcement 25 February 2022) and these will be used when the resource is updated in the future. In the Company’s opinion there is reasonable potential for both gold and silver to be extracted and sold.

^ The information in this report that relates to Mineral Resources or Ore Reserves is based on information provided in the following ASX announcement: 17 Nov 2021 - MAIDEN JORC RESOURCE 529,000 OUNCES @ 6.81G/T (AuEq*), which includes the full JORC MRE report, also available on the Mithril Resources Limited Website.

The Company confirms that it is not aware of any new information or data that materially affects the information included in the original market announcement and that all material assumptions and technical parameters underpinning the estimates in the relevant market announcement continue to apply and have not materially changed. The company confirms that the form and context in which the Competent Person’s findings are presented have not been materially modified from the original market announcement.

Mining study (conceptual) and metallurgical test work supports the development of the El Refugio-La Soledad resource with conventional underground mining methods indicated as being appropriate and with high gold-silver recovery to produce metal on-site with conventional processing.

Mithril is currently exploring in the Copalquin District to expand the resource footprint, demonstrating its multi-million-ounce gold and silver potential. Mithril has an exclusive option to purchase 100% interest in the Copalquin mining concessions by paying US$10M on or any time before 7 August 2028.

-ENDS-

Released with the authority of the Board.

For further information contact:

|

John Skeet Managing Director and CEO This email address is being protected from spambots. You need JavaScript enabled to view it. +61 435 766 809 |

NIKLI COMMUNICATIONS Corporate Communications This email address is being protected from spambots. You need JavaScript enabled to view it. This email address is being protected from spambots. You need JavaScript enabled to view it. |

The Australian Securities Exchange has not reviewed and does not accept responsibility for the accuracy or adequacy of this release.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Competent Persons Statement - JORC

The information in this announcement that relates to metallurgical test results, mineral processing and project development and study work has been compiled by Mr John Skeet who is Mithril’s CEO and Managing Director. Mr Skeet is a Fellow of the Australasian Institute of Mining and Metallurgy. This is a Recognised Professional Organisation (RPO) under the Joint Ore Reserves Committee (JORC) Code.

Mr Skeet has sufficient experience of relevance to the styles of mineralisation and the types of deposits under consideration, and to the activities undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee (JORC) Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr Skeet consents to the inclusion in this report of the matters based on information in the form and context in which it appears. The Australian Securities Exchange has not reviewed and does not accept responsibility for the accuracy or adequacy of this release.

The information in this announcement that relates to sampling techniques and data, exploration results and geological interpretation for Mithril’s Mexican project, has been compiled by Mr Patrick Loury who is Mithril’s Project Consultant. Mr Loury is a member of the American Institute of Professional Geologists and a Certified Professional Geologist (CPG). This is a Recognised Professional Organisation (RPO) under the Joint Ore Reserves Committee (JORC) Code.

Mr Loury has sufficient experience of relevance to the styles of mineralisation and the types of deposits under consideration, and to the activities undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee (JORC) Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr Loury consents to the inclusion in this report of the matters based on information in the form and context in which it appears.

The information in this announcement that relates to Mineral Resources is reported by Mr Rodney Webster, Principal Geologist at AMC Consultants Pty Ltd (AMC), who is a Member of the Australasian Institute of Mining and Metallurgy. The report was peer reviewed by Andrew Proudman, Principal Consultant at AMC. Mr Webster is acting as the Competent Person, as defined in the 2012 Edition of the Joint Ore Reserves Committee (JORC) Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves, for the reporting of the Mineral Resource estimate. A site visit was carried out by Jose Olmedo a geological consultant with AMC, in September 2021 to observe the drilling, logging, sampling and assay database. Mr Webster consents to the inclusion in this report of the matters based on information in the form and context in which it appears

Qualified Persons – NI 43-101

Scientific and technical information in this Report has been reviewed and approved by Mr John Skeet (FAUSIMM, CP) Mithril’s Managing Director and Chief Executive Officer. Mr John Skeet is a qualified person within the meaning of NI 43-101.

Samples are sent to ALS Global with sample preparation performed in Chihuahua City, Mexico and assaying of sample pulps performed in North Vancouver, BC, Canada.

Table 4 Drill samples with AuEq grades greater than or equal to 0.1 g-t AuEq

|

Hole ID |

Sample ID |

From (m) |

To (m) |

Au ppm |

Ag ppm |

AuEq g/t* |

|

MTH-LS25-32A |

743134 |

10.22 |

10.72 |

0.045 |

4.3 |

0.11 |

|

MTH-LS25-32A |

743174 |

241.35 |

242.00 |

0.064 |

3.1 |

0.11 |

|

MTH-LS25-32A |

743176 |

242.00 |

243.00 |

0.065 |

2.3 |

0.1 |

|

MTH-LS25-32A |

743183 |

252.55 |

253.43 |

0.73 |

5.2 |

0.8 |

|

MTH-LS25-32A |

743184 |

253.43 |

253.93 |

0.089 |

4.9 |

0.16 |

|

MTH-LS25-32A |

743282 |

505.90 |

506.95 |

0.031 |

8.1 |

0.15 |

|

MTH-LS25-32A |

743285 |

508.70 |

509.30 |

0.033 |

4.6 |

0.1 |

|

MTH-LR25-33 |

744226 |

297.00 |

298.00 |

0.596 |

99.3 |

2.01 |

|

MTH-LP25-34 |

744401 |

27.00 |

29.00 |

0.143 |

6 |

0.23 |

|

MTH-LP25-34 |

744407 |

35.55 |

36.60 |

0.045 |

4.1 |

0.1 |

|

MTH-LP25-34 |

744493 |

248.00 |

248.94 |

0.169 |

24.4 |

0.52 |

|

MTH-LS25-35 |

743436 |

156.00 |

156.90 |

0.803 |

3.6 |

0.85 |

|

MTH-LS25-35 |

743437 |

156.90 |

158.00 |

9.95 |

44.6 |

10.59 |

|

MTH-LS25-35 |

743438 |

158.00 |

158.70 |

0.124 |

4.6 |

0.19 |

|

MTH-LS25-35 |

743439 |

158.70 |

159.54 |

0.156 |

3.1 |

0.2 |

|

MTH-LS25-35 |

743441 |

159.54 |

160.20 |

0.066 |

3.3 |

0.11 |

|

MTH-LS25-35 |

743442 |

160.20 |

160.72 |

0.226 |

7 |

0.33 |

|

MTH-LS25-35 |

743444 |

161.50 |

162.00 |

0.227 |

6.1 |

0.31 |

|

MTH-LS25-35 |

743446 |

163.00 |

164.00 |

0.063 |

4.3 |

0.12 |

|

MTH-LS25-35 |

743448 |

165.00 |

165.65 |

0.051 |

6.8 |

0.15 |

|

MTH-LS25-35 |

743483 |

252.70 |

253.20 |

0.129 |

12.2 |

0.3 |

|

MTH-LS25-35 |

743563 |

391.70 |

393.00 |

0.048 |

6.4 |

0.14 |

|

MTH-LS25-35 |

743564 |

393.00 |

393.80 |

0.065 |

7.1 |

0.17 |

|

MTH-LS25-36 |

743573 |

103.30 |

103.80 |

3.21 |

13.8 |

3.41 |

|

MTH-LS25-36 |

743591 |

126.00 |

127.50 |

0.074 |

3 |

0.12 |

|

MTH-LS25-36 |

743619 |

169.70 |

170.20 |

49.9 |

78.1 |

51.02 |

|

MTH-LS25-36 |

743621 |

170.20 |

170.70 |

0.283 |

3.6 |

0.33 |

|

MTH-LS25-36 |

743622 |

170.70 |

171.35 |

4.84 |

104 |

6.33 |

|

MTH-LS25-36 |

743623 |

171.35 |

171.85 |

0.414 |

3.5 |

0.46 |

|

MTH-LS25-36 |

743624 |

171.85 |

172.45 |

0.215 |

6 |

0.3 |

|

MTH-LS25-36 |

743626 |

172.45 |

173.00 |

0.776 |

28.3 |

1.18 |

|

MTH-LS25-36 |

743627 |

173.00 |

173.45 |

0.131 |

6.2 |

0.22 |

|

MTH-LS25-36 |

743631 |

174.50 |

175.35 |

0.378 |

20.5 |

0.67 |

|

MTH-LS25-36 |

743633 |

175.85 |

176.45 |

0.097 |

4.4 |

0.16 |

|

MTH-LS25-36 |

743637 |

179.30 |

181.00 |

0.08 |

3.3 |

0.13 |

|

MTH-LS25-36 |

743660 |

248.15 |

248.70 |

0.05 |

4.4 |

0.11 |

|

MTH-LS25-36 |

743673 |

315.00 |

316.40 |

0.068 |

4 |

0.13 |

|

MTH-LS25-36 |

743719 |

386.40 |

387.30 |

0.082 |

5.1 |

0.15 |

|

MTH-ZG25-37 |

816651 |

23.60 |

24.20 |

0.032 |

8.6 |

0.15 |

|

MTH-ZG25-37 |

826011 |

298.50 |

300.00 |

0.033 |

24 |

0.38 |

|

MTH-ZG25-37 |

826044 |

341.00 |

341.90 |

0.05 |

50.9 |

0.78 |

|

MTH-ZG25-37 |

826045 |

341.90 |

342.40 |

0.025 |

6.3 |

0.12 |

|

MTH-ZG25-37 |

826047 |

342.97 |

344.00 |

0.042 |

14.2 |

0.24 |

|

MTH-ZG25-37 |

826056 |

350.00 |

351.00 |

0.101 |

49.6 |

0.81 |

|

MTH-ZG25-37 |

826057 |

351.00 |

352.00 |

0.032 |

4.7 |

0.1 |

|

MTH-ZG25-37 |

826059 |

352.62 |

353.58 |

0.044 |

7.4 |

0.15 |

|

MTH-ZG25-37 |

826061 |

354.08 |

354.75 |

0.044 |

11.6 |

0.21 |

|

MTH-ZG25-37 |

826083 |

372.77 |

373.65 |

0.027 |

4.8 |

0.1 |

|

MTH-ZG25-37 |

826091 |

379.50 |

380.05 |

0.046 |

9.6 |

0.18 |

|

MTH-ZG25-37 |

826099 |

386.30 |

386.90 |

0.068 |

7.2 |

0.17 |

|

MTH-ZG25-37 |

826101 |

386.90 |

387.90 |

0.439 |

23.9 |

0.78 |

|

MTH-ZG25-37 |

826104 |

389.10 |

389.76 |

3.49 |

127 |

5.3 |

|

MTH-LS25-38 |

743765 |

321.90 |

322.67 |

0.273 |

6.9 |

0.37 |

|

MTH-LS25-38 |

743766 |

322.67 |

323.27 |

0.11 |

8.8 |

0.24 |

|

MTH-LS25-38 |

743771 |

326.00 |

327.40 |

0.094 |

2.8 |

0.13 |

|

MTH-LS25-38 |

743774 |

329.20 |

331.05 |

0.082 |

2.6 |

0.12 |

|

MTH-LS25-38 |

743778 |

332.33 |

333.00 |

0.171 |

8 |

0.29 |

|

MTH-LS25-38 |

743796 |

350.30 |

351.00 |

0.137 |

4.6 |

0.2 |

|

MTH-LS25-38 |

743810 |

363.00 |

364.30 |

0.114 |

2.7 |

0.15 |

|

MTH-LS25-38 |

743812 |

366.00 |

366.72 |

0.146 |

1 |

0.16 |

|

MTH-LS25-38 |

743871 |

433.70 |

435.00 |

0.186 |

2.8 |

0.23 |

|

MTH-LS25-38 |

743889 |

453.00 |

453.70 |

0.117 |

3.8 |

0.17 |

|

MTH-LS25-38 |

743898 |

464.12 |

464.75 |

0.036 |

4.9 |

0.11 |

|

MTH-LS25-38 |

743915 |

483.25 |

484.17 |

0.03 |

25.3 |

0.39 |

|

MTH-LS25-38 |

743940 |

504.75 |

505.85 |

0.028 |

5.6 |

0.11 |

|

MTH-LS25-38 |

743941 |

505.85 |

506.60 |

0.069 |

6.4 |

0.16 |

|

MTH-LS25-38 |

743942 |

506.60 |

507.30 |

0.035 |

5.7 |

0.12 |

|

MTH-LS25-38 |

743943 |

507.30 |

508.85 |

0.055 |

6.5 |

0.15 |

|

MTH-LS25-38 |

743948 |

513.55 |

514.30 |

0.125 |

2.1 |

0.16 |

|

MTH-ZG25-39 |

826205 |

204.70 |

205.55 |

0.021 |

6.8 |

0.12 |

|

MTH-ZG25-39 |

826224 |

260.15 |

261.00 |

0.11 |

0.8 |

0.12 |

|

MTH-ZG25-39 |

826258 |

327.75 |

328.47 |

0.039 |

8.3 |

0.16 |

|

MTH-ZG25-39 |

826261 |

329.00 |

329.95 |

0.047 |

12.1 |

0.22 |

|

MTH-ZG25-39 |

826262 |

329.95 |

331.35 |

0.08 |

8.6 |

0.2 |

|

MTH-ZG25-39 |

826295 |

368.50 |

369.00 |

0.029 |

5.6 |

0.11 |

|

MTH-ZG25-39 |

826296 |

369.00 |

369.60 |

0.479 |

35.9 |

0.99 |

|

MTH-ZG25-39 |

826297 |

369.60 |

370.70 |

0.222 |

23.2 |

0.55 |

|

MTH-ZG25-39 |

826298 |

370.70 |

371.20 |

0.065 |

21.1 |

0.37 |

|

MTH-ZG25-39 |

826299 |

371.20 |

371.70 |

0.02 |

10.9 |

0.18 |

|

MTH-ZG25-39 |

826319 |

395.72 |

396.54 |

0.038 |

9.5 |

0.17 |

|

MTH-ZG25-39 |

826345 |

440.90 |

442.00 |

0.019 |

9.5 |

0.15 |

|

MTH-ZG25-39 |

826346 |

442.00 |

443.15 |

0.016 |

7.5 |

0.12 |

JORC Code, 2012 Edition – Table 1

Section 1 Sampling Techniques and Data

|

Criteria |

JORC Code explanation |

Commentary |

|

Sampling techniques |

|

|

|

Drilling techniques |

|

|

|

Drill sample recovery |

|

|

|

Logging |

|

|

|

Sub-sampling techniques and sample preparation |

|

|

|

Quality of assay data and laboratory tests |

|

|

|

Verification of sampling and assaying |

|

|

|

Location of data points |

|

|

|

Data spacing and distribution |

|

|

|

Orientation of data in relation to geological structure |

|

|

|

Sample security |

|

|

|

Audits or reviews |

|

|

Section 2 Reporting of Exploration Results

|

Criteria |

JORC Code explanation |

Commentary |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Mineral tenement and land tenure status |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Exploration done by other parties |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Geology |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Drill hole Information |

|

No drilling results in this announcement |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Data aggregation methods |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Relationship between mineralisation widths and intercept lengths |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Diagrams |

|

See figures in announcement |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Balanced reporting |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Other substantive exploration data |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Further work |

|

|

1 See ‘About Copalquin Gold Silver Project’ section for JORC MRE details and AuEq. calculation.