Highlights

- Mixed heavy and light rare earth oxide concentrates produced from Halleck Creek’s allanite-based ore as part of the US Department of Defense’s (“DoD”) on-going Defense Advanced Research Projects Agency (“DARPA”) Environmental Microbes as a BioEngineering Resource (“EMBER”) project.

- Results include:

- 97.1% pure Heavy Rare Earth Oxide (“HREO”)

- 96.4% pure Light Rare Earth Oxide (“LREO”)

- First production of Light Rare Earth Oxides (“LREO”) and Heavy Rare Earth Oxides (“HREO”) using Halleck Creek Ore

DENVER, Aug. 15, 2025 (GLOBE NEWSWIRE) -- American Rare Earths Limited (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) (“ARR” or “the Company”) announced today that the University of Kentucky (“UK”) produced a heavy rare earths oxide concentrate and light rare earths oxide concentrate from Halleck Creek’s allanite-based ore. These concentrates are precursors to separated rare earth element (“REE”) oxides and this is the first time that they have been produced from Halleck Creek ore.

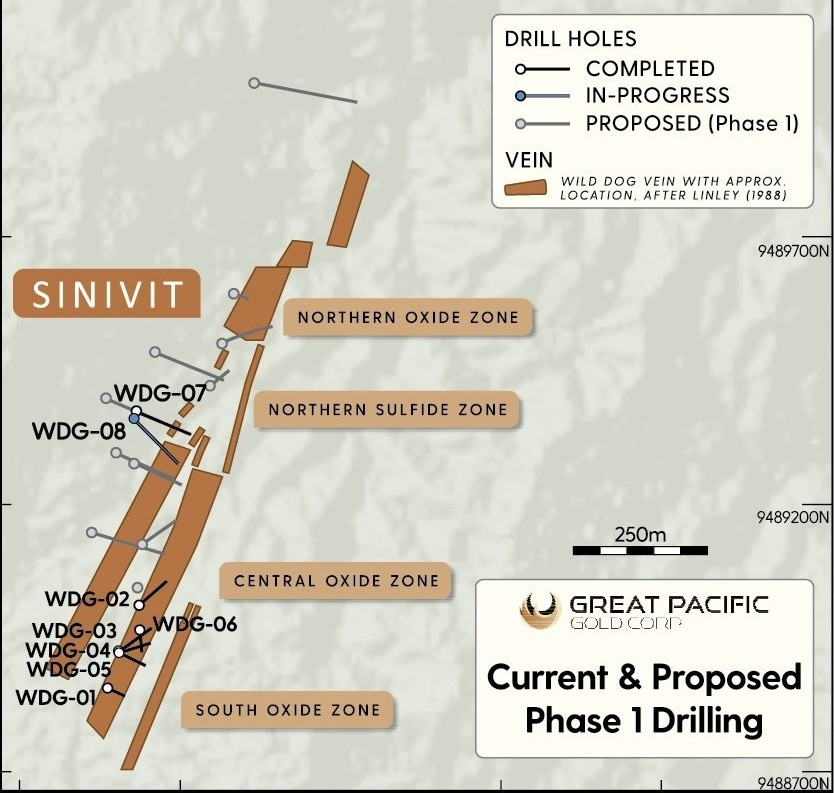

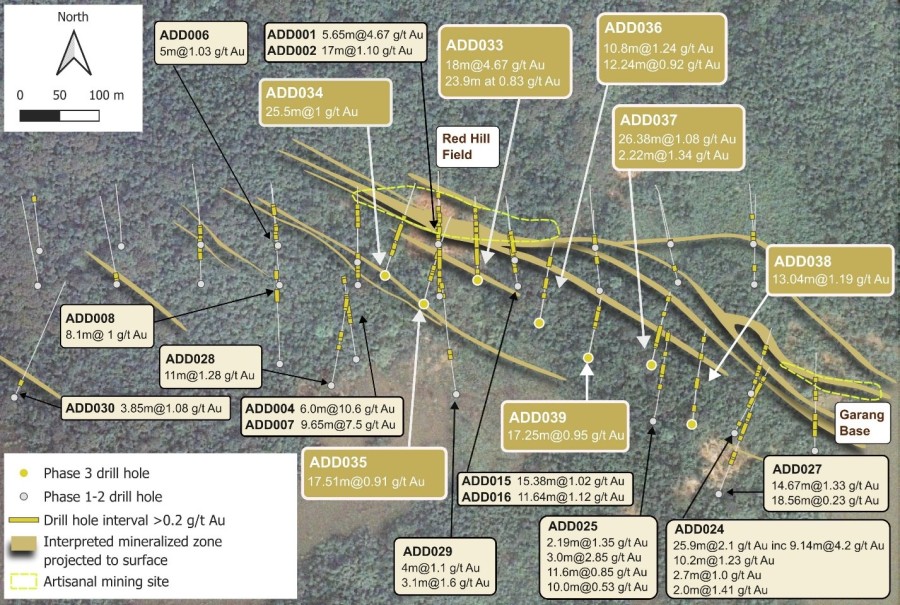

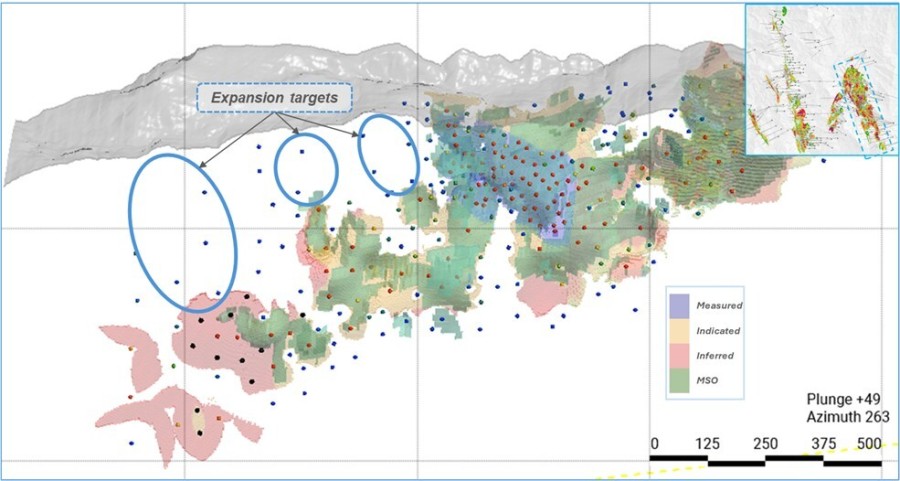

American Rare Earths is a part of the US Department of Defenses’ ongoing DARPA EMBER project. This project’s goal is to develop a biotechnology-based separation and purification strategy for REEs. Since 2023, ARR has provided ~840kg of Halleck Creek ore to the project from approximately 36 drill holes (Figure 1 and Table 1), which UK, in collaboration with the Lawrence Livermore National Lab (i.e. US Department of Energy laboratory, “LLNL”) and Penn State University, have processed into leachates for bio-recovery and traditional solvent extraction recovery of REEs. This consortium, known as SynBREE, led by LLNL scientists, has been working together to research and develop bio-recovery of rare earth elements using the Lanmodulin protein and its derivatives.

Why it matters? The production of this material provides a meaningful development for the Halleck Creek project as it demonstrates that rare earth oxides, of relatively high purity can be produced from Halleck Creek’s allanite-based ore. Encouragingly, the SynBREE consortium’s biotechnology flowsheet, while at laboratory research stage and yet to be commercially proven, shows the method successfully extracts REE from allanite minerals, and could provide an alternate separation process to be considered in the future.

At this stage, the SynBREE consortium’s research is outside of the scope of the Company’s on-going Pre-Feasibility Study (“PFS”) mineral processing flow-sheet development. American Rare Earths is currently testing conventional mineral processing techniques and progressing the optimization work announced earlier this month, while at the same time continuing to review the potential of new, innovative technology.

Interim CEO, Joe Evers, commented, “Our collaboration with the SynBREE consortium continues to achieve significant milestones. These results provide a very meaningful third-party validation that light and heavy rare earths oxides can be produced from the Halleck Creek allanite hosted ore body. Both these oxides are used in the production of permanent magnets.”

These results are part of ongoing research for the DARAPA EMBER project. The rare earth oxides produced by UK provide the feedstock LLNL uses to test separation columns using Lanmodulin. It should be noted that the oxides UK produced are not final products, they are a precursor to individual separated rare earth oxides. Furthermore, the research flowsheet used by UK differs from flowsheets being developed by Wyoming Rare (USA) Inc (“WRI”), the wholly owned subsidiary of ARR. As a part of the on-going Pre-Feasibility Study work, WRI is using conventional mineral processing techniques and equipment for the flow-sheet design.

UK created LREO powder and HREO powder using reverse circulation cuttings from drill holes across the Halleck Creek project area. UK created this material independently from ARR as part of the DARPA EMBER SynBREE project led by Lawrence Livermore National Lab (LLNL), and Penn State University. The methods UK used to create this material are independent from any methods used by ARR for mineral processing and leaching.

UK used heavy liquid separation to concentrate allanite in RC feedstock. UK used hydrochloric acid to leach the allanite ore. UK used sodium hydroxide to remove approximately 98% of iron, aluminum, and silica from the leachate solution. REE losses in impurity removal were approximately 15%.

UK used D2EHPA and hydrochloric acid for solvent extraction to create LREE- and HREE-enriched solutions. UK used oxalic acid to create a LREE oxalate and an HREE oxalate powder. UK then calcined the oxalates to create a light rare earth oxide (“LREO”) and a heavy rare earth oxide (“HREO”). UK recovered approximately 82% of total rare earths from the leachate solution. The LREO is approximately 96.4% pure and the HREO is approximately 97.1% pure. More information on the results can be found at: Click Here.

About American Rare Earths Limited:

American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) is a critical minerals company at the forefront of reshaping the U.S. rare earths industry. Through its wholly owned subsidiary, Wyoming Rare (USA) Inc. (“WRI”), the company is advancing the Halleck Creek Project in Wyoming—a world-class rare earth deposit with the potential to secure America’s critical mineral independence for generations. Located on Wyoming State land, the Cowboy State Mine within Halleck Creek offers cost-efficient open-pit mining methods and benefits from streamlined permitting processes in this mining-friendly state.

With plans for onsite mineral processing and separation facilities, Halleck Creek is strategically positioned to reduce U.S. reliance on imports—predominantly from China—while meeting the growing demand for rare earth elements essential to defense, advanced technologies, and economic security. As exploration progresses, the project’s untapped potential on both State and Federal lands further reinforces its significance as a cornerstone of U.S. supply chain security. In addition to its resource potential, American Rare Earths is committed to environmentally responsible mining practices and continues to collaborate with U.S. Government-supported R&D programs to develop innovative extraction and processing technologies for rare earth elements.

For Further Information

Susan Assadi

Media Relations US

347-977-7125

Beverly Jedynak

Investor Relations US

312-943-1123