HIGHLIGHTS

- Verification drill hole program confirms wide spread lithium mineralisation

- Drill results combined with the previously announced depth of the Salar (500+ m) indicates the potential for large lithium brine resource

- Drill hole RG-2017-24T returns a range of between 375mg/l Li to 657mg/l Li over 90m

- Drill hole RG-2017-7T returns range of between 384mg/l Li to 535mg/l Li over 89m

- Drill hole RG-2017-1T returns range of between 385mg/l Li to 411mg/l Li over 86m

- Drill hole RG-2017-22T returns range of between 356mg/l Li to 385mg/l Li over 92m

- Drill hole RG-2017-27T returns range of between 327mg/l Li to 433mg/l Li over 74m

- NI 43-101 Mineral Resource estimate by end of February 2018

TORONTO, Jan. 24, 2018 (GLOBE NEWSWIRE) -- LSC Lithium Corporation (“LSC” or together with its subsidiaries, the “Company”) (TSXV:LSC) is pleased to announce drill results from its Rio Grande lithium in brine project located in the Argentinian section of the Lithium Triangle. These verification program results verify and support historic drill hole results which established wide spread lithium mineralisation over the 18,000 ha salar surface.

The Company’s CEO Ian Stalker commented “This eight hole verification program intersects extensive lithium mineralisation on this large 18,000 ha salar surface. Furthermore, recently announced CS-AMT results indicate that the mineralisation drilled could extend to in excess of 500m below surface in two depositional centers of the salar in the north and center respectively. We intend to test these deeper targets as part of the 2018 Mineral Resource upgrade program.”

The aim of the eight hole drill program was to verify the historical results reported for 33 holes drilled across the salar by ADY Resources Ltd. (“ADY”). These results, including those reported by LSC, will be utilised in the NI 43-101 Mineral Resource estimate which is planned for issue by the end of February 2018. The ADY drill holes were all terminated at approximately 50m below surface. A decision to extend the LSC drill holes to a planned 100m was made to test potential high-grade lithium mineralisation at depth. This has proved successful as lithium mineralisation down hole trends tend to increase in grade at depth.

Drilling was carried out utilising a wireline triple tube core barrel system recovering HQ size core for geological logging and Relative Brine Release Capacity (RBRC) analysis. While drilling in the center of the salar in proximity to drill holes SRG-2017-22T and SRG-2017-18T, unconsolidated volcanic derived sands were encountered which prevented both holes drilling to the planned depth of 100m below surface, reaching 60m and 84.5m respectively. In some cases it was deemed necessary to repeat some of the drill holes in the top 20m to 50m below surface where either the packer equipment was inoperable or brine recoveries where negative with corresponding historical ADY data indicating positive brine samples at the particular down hole elevation. The packer sampling in the eight LSC twin holes was designed to replicate the intervals within the ADY drill holes and this was achieved to an acceptable level.

| Table 1: Verification Diamond Drill Program Summary – Salar de Rio Grande | ||||||||

| Hole | POSGAR 94 DATUM | Elevation (Z) | Depth (m) | Azimuth | Dip | Method | Bit Size | |

| East (X) | North (Y) | |||||||

| SRG-2017-35T | 2587211.0 | 7230569.0 | 3701.89 | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-07T | 2582718.0 | 7229102.0 | 3701.57 | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-01T | 2586170.0 | 7234917.0 | 3701.92 | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-22T | 2583870.0 | 7223137.0 | 3704.78 | 60.0 | 0 | 90 | DDH | HQ |

| SRG-2017-27T | 2585891.0 | 7221137.0 | TBA | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-24T | 2587912.0 | 7223137.0 | 3705.20 | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-32T | 2588923.0 | 7219137.0 | 3705.65 | 100.0 | 0 | 90 | DDH | HQ |

| SRG-2017-18T | 2584880.0 | 7225137.0 | 3702.99 | 84.5 | 0 | 90 | DDH | HQ |

Sampling and QA/QC

Brine sampling for packer tests involved collection of brine from the sample interval in a 20-litre container, which was flushed with fresh brine several times prior to collection of the sample. Brine was poured into 1-litre sample bottles which had been previously flushed with fresh brine from the 20-litre container several times. Sample bottles were filled to the top to eliminate the inclusion of air and sealed with a leak proof lid. Samples were labelled and labels covered in clear tape to prevent erasure of sample information. All samples remained in the possession of the site geologist until delivery to Alex Stewart Argentina (“ASA”) S.A. Laboratory in Jujuy, Argentina by courier. Brine sampling for the pump stress test involved collection of samples from a valve attached to the pump outlet. Brine was allowed to flush and then fresh brine was used to wash the sample bottle several times before collecting the sample. Sample bottles were 1-litre in size and were filled to the top to prevent entrance of air. The samples were sealed with a leak proof lid, labelled and the label covered by clear tape. Samples remained in the possession of the site until delivery by courier to the assay laboratory.

RBRC samples were cut to length using a hack saw, bubble wrapped for protection and then placed in PVC tubes which were sealed with packaging tape. The samples were labelled and the labels wrapped in clear tape. Samples remained in the custody of the site geologist until shipped. Brine (20-litres) from each of the holes from which the samples were collected was also shipped to DBSA as part of the sample test protocol. DBSA is independent of LSC.

LSC has a well-developed QA/QC program. Brine assays are undertaken at ASA in Jujuy, Argentina. ASA is independent of LSC and has significant experience in assaying lithium brines and is certified to ISO17025 standards. Brine assays are undertaken using ICP, gravimetric, potentiometric and volumetric methods as detailed in a press release from LSC dated April 10, 2017.

ASA runs internal duplicates at a rate of 1 in 20. LSC inserts blanks and standards in sample batches at a rate of 1 in 20. Standards are internal standards developed by LSC that have been independently certified by round robin testing. LSC uses distilled water as blanks.

Qualified Person/Data Verification

The scientific and technical information included in this press release is based upon information prepared and approved by Donald H. Hains, P.Geo. Mr. Hains is a qualified person, as defined in NI 43-101 and is independent of LSC and ADY. Mr. Hains has verified all sampling, analytical and test data underlying the information contained in this press release by on-site inspection during brine sampling and review of certified assay certificates against the assay data base.

ABOUT LSC LITHIUM CORPORATION:

LSC Lithium has amassed a large portfolio of prospective lithium rich salars and is focused on developing its tenements located in five salars: Pozuelos, Pastos Grandes, Rio Grande, Salinas Grandes, and Jama. All LSC tenements are located in the “Lithium Triangle,” an area at the intersection of Argentina, Bolivia, and Chile where the world’s most abundant lithium brine deposits are found. LSC Lithium has a land package portfolio totaling approximately 300,000 hectares, which represents extensive lithium prospective salar holdings in Argentina.

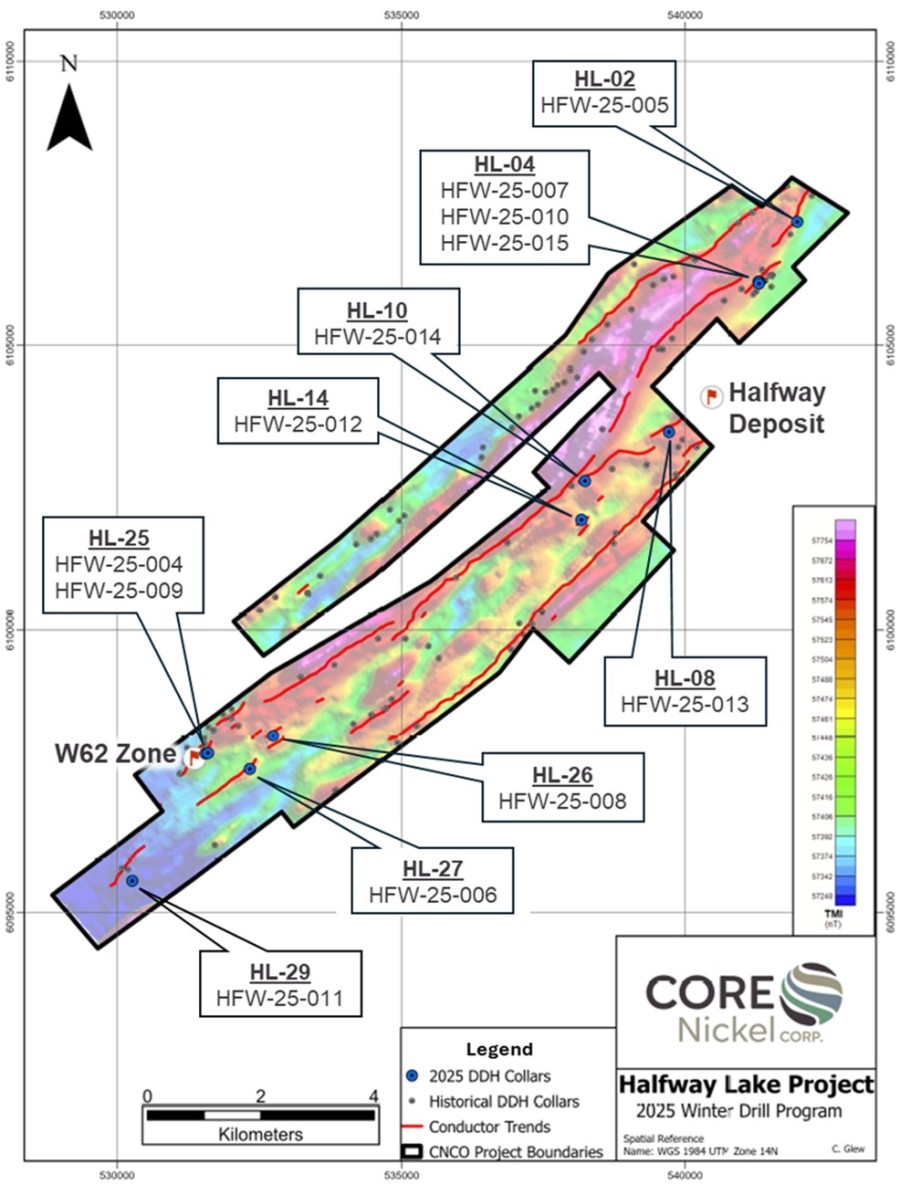

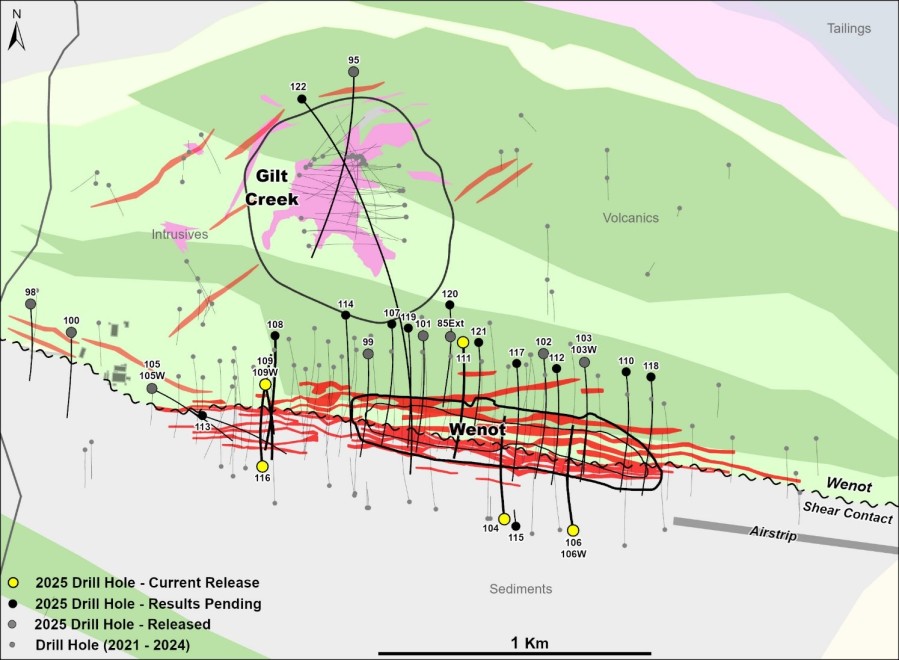

Map 1: LSC Due Diligence Drill Hole Locations