TORONTO, March 20, 2018 /CNW/ - First Cobalt Corp. (TSX-V: FCC, ASX: FCC, OTCQB: FTSSF) (the "Company") today announces the commencement of a metallurgical study to be conducted on a high grade inventory of refinery residue and crushed waste rock material located near the First Cobalt mill facility in the Canadian Cobalt Camp. This study is intended to advance the Company's early cash flow strategy by assessing an optimal flow sheet for recovering cobalt and silver, as well as arsenic removal and stabilization.

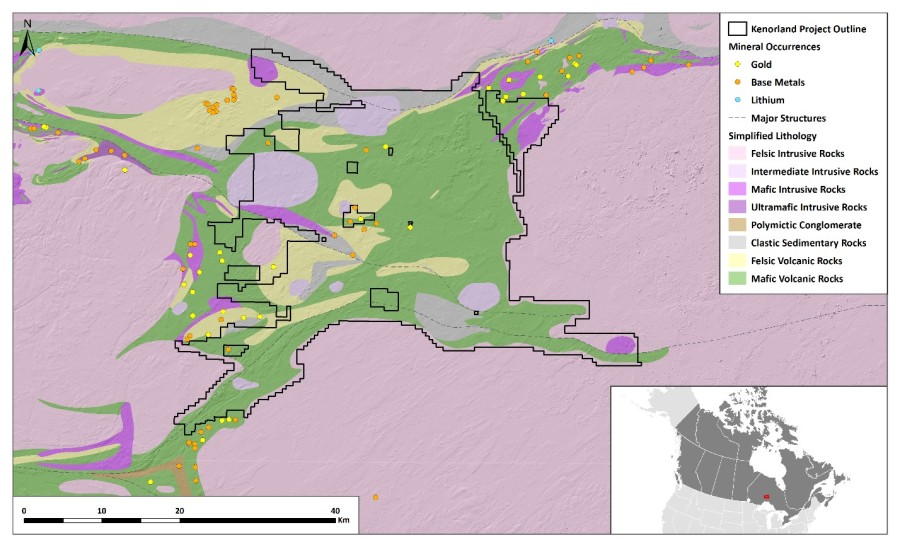

Image 1. Pile of crushed waste rock material at First Cobalt mill site.

Highlights

- Program will provide further insights into opportunities for early cash flow from processing surface muckpiles from historic underground mining operations

- Testing will be done on three piles with a historic resource estimate, prepared before the Company acquired an interest in the properties, totalling approximately 6,500 tonnes with average grades ranging from 0.65% to 1.55% cobalt (non-compliant with NI 43-101)*

- Metallurgical testwork aimed at elaborating a process flow sheet based on analytical characterization of the samples, gravity concentration, hydrometallurgical recovery of cobalt and silver, as well as arsenic removal and stabilization

- Success could have broader implications for the ongoing assessment of processing options for historical mine material throughout the Cobalt Camp using First Cobalt's mill and refinery

Trent Mell, President & Chief Executive Officer, commented:

"The results of this program will improve our understanding of processing options for materials from the Cobalt Camp. While we continue to advance our exploration strategy, another key strategic objective is to seize upon the opportunity to generate early cash flow from material left on surface from historic mining operations. This study is an important step toward our goal of producing cobalt battery materials in North America."

First Cobalt has partnered with Dundee Sustainable Technologies in Quebec to develop a flow sheet for potentially processing the piles using the First Cobalt mill equipment and the First Cobalt Refinery and to understand the benefits of integrating Dundee's arsenic removal and stabilization technology.

According to a 2014 historic resource estimate, which is non-compliant with NI 43-101 and was prepared by an external consultant for internal use for a previous property owner, the three piles contain approximately 6,500 tonnes* of material with average grades ranging from 0.65% to 1.55% cobalt (see table 1). One of the piles consists of broken rock material from the site of the old Kerr mine and mill. Another pile consists of previously processed high grade refinery residue material containing primarily silver and cobalt and the third pile is a mixture of both materials.

Table 1. Historical Resource Estimate - Averages of samples taken from three piles to be studied.

|

Pile |

Est. |

# of |

Avg. |

Avg. Ag g/t |

Avg. |

|

Refinery Residue |

1,208 |

10 |

1.55 |

1,142 |

0.54 |

|

Crushed Waste Rock |

3,906 |

122 |

0.65 |

540 |

0.23 |

|

Mixed |

1,474 |

125 |

1.27 |

1035 |

0.44 |

|

* Non-compliant with NI 43-101. Actual tonnage could be lower due to historical relocation and recontouring of the piles from their original location and bulk sampling and testing campaigns. See Historical Estimates footnote for additional details. |

The results of this study will advance our knowledge of how to improve cobalt recovery out of materials in the Cobalt Camp and could lead to early cash flow from the processing of these high grade piles. Historic processing of material from this Camp focused on recovery of silver and did not focus on the recovery of cobalt.

This study is supported by a mineralogical assessment of sample material from various historical mines conducted by XPS Consulting and Testwork Services (see October 5, 2017 press release). The XPS study concluded that the various cobalt-rich and silver-rich mineralization styles found in the Camp may be processed using similar flowsheets throughout the Cobalt Camp.

Work is ongoing for the more extensive muckpile sampling program at a number of historic mining operations throughout the Cobalt Camp, the details of which were announced November 15, 2017.

The Dundee study is expected to be completed by the end of the second quarter and aims to advance the processing flowsheet based on studying the analytical characterization of the submitted material, the amenability of the material to be concentrated by gravity, the recovery of metallic values by hydrometallurgical process and the Dundee Sustainable Technologies processes for arsenic removal and stabilization.

Qualified and Competent Person Statement

Peter Campbell, P.Eng., is the Qualified Person as defined by National Instrument 43-101 who has reviewed and approved the contents of this news release. Mr. Campbell is also a Competent Person (as defined in the JORC Code, 2012 edition) who is a practicing member of the Professional Engineers of Ontario (being a 'Recognised Professional Organisation' for the purposes of the ASX Listing Rules). Mr. Campbell is employed on a full-time basis as Vice President, Business Development for First Cobalt. He has sufficient experience that is relevant to the activity being undertaken to qualify as a Competent Person as defined in the JORC Code.

Historic Estimates

This news release contains references to a historical estimate which cannot and should not be relied upon. First Cobalt is not treating the historical estimate as a current mineral resource or mineral reserve. The historical estimate was prepared by an external consultant for internal use for a previous property owner in 2014. A qualified person has not done sufficient work to classify the historical estimate as a current mineral resource or mineral reserve. The historical estimate does not use categories that conform to current CIM Definition Standards on Mineral Resources and Mineral Reserves as outlined in NI 43-101 and has not been redefined to conform to current CIM Definition Standards. More work, including, but not limited to volumetric measurements and confirmatory sampling will be required to conform the estimate to current CIM Definition Standards. Investors are cautioned that the historical estimate does not mean or imply that economic deposits exist. First Cobalt has not undertaken any independent investigation of the historical estimate nor has it independently analyzed the results of the previous analysis in order to verify the accuracy of the information.