OTTAWA, Sept. 28, 2017 (GLOBE NEWSWIRE) -- Focus Graphite Inc. (TSX-V:FMS) (OTCQX:FCSMF) (FSE:FKC) (“Focus” or the “Company”) is pleased to announce excellent results from ongoing independent laboratory tests comparing long term cycling performance of Lac Knife surface coated spherical crystalline fine flake graphite against commercially competitive standard grades of coated crystalline flake graphite in the anodes of CR2016 coin cells.

The results presented are a follow up from data presented in Focus’ November 25, 2015 news release where similar tests were run on Lac Knife’ standard grade spherical graphite. Those tests exhibited essentially zero loss in capacity after 110 cycles versus two commercially competitive grades that showed losses of 4.4% and 6.4% over the same number of cycles.

Testing was conducted at a globally recognized laboratory in Europe. The name of the laboratory is being withheld because of commercial and competitive confidentiality.

Ongoing Life Cycle Testing

On November 25, 2015 Focus Graphite published data showing that its Lac Knife Standard Grade of uncoated and coated spherical graphite exhibited essentially zero loss in capacity after 110 cycles versus two commercially competitive grades that showed losses of 4.4% and 6.4% over the same number of cycles.

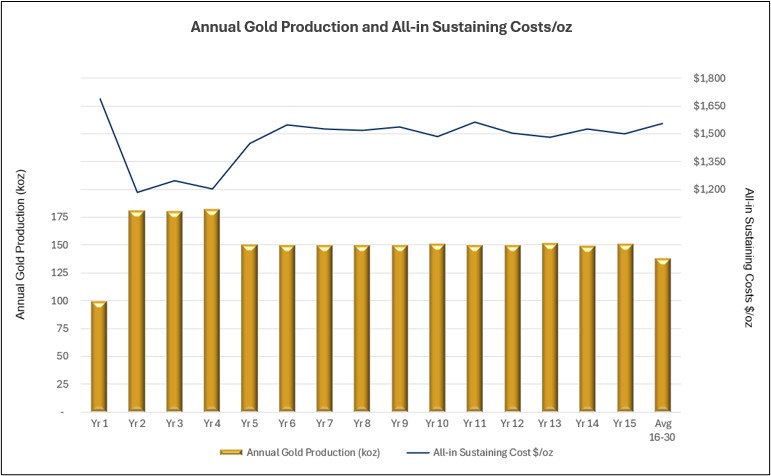

In a presentation to the International Battery Seminar in Fort Lauderdale, Florida on March 26, 2017, Dr. Joseph Doninger, Focus’ Director of Manufacturing and Technology presented long term cycling test results showing that the zero loss in capacity of the Standard Grade of coated spherical graphite lasted for 250 cycles and showed a loss of only 4.5% in capacity after 570 cycles compared with losses of 11.7% after 440 cycles and 10.5% after 510 cycles for a competitive supplier’s coated spherical graphite.

He said that projecting these results suggests that Lac Knife’s coated SPG could last beyond 2000 cycles in full sized batteries. “A good rule of thumb to use in comparing the long term cycling performance of different graphites in Lithium Ion batteries is determining how many cycles a battery will last before losing 20% of its capacity,” Dr. Doninger said.

Focus Graphite is the sole owner of the high purity Lac Knife natural flake graphite project in the Côte-Nord region of northeastern Québec.

The Company’s aim is to become one of the lowest cost producers of high-purity technology graphite. The purpose of its ongoing battery materials testing efforts is to validate the commercial viability of the high purity crystalline flake graphite recovered from its Lac Knife deposit, and to demonstrate that Lac Knife graphite holds the potential to improve the performance of anodes in Lithium Ion batteries. (See May 27th, 2014 and February 26th, 2015 News Releases).

The properties of the flake graphite recovered from the Lac Knife high quality and high carbon content graphite deposit, allow for the recovery of concentrate that grades 98% C even in the finer size fractions down to 200 mesh (75 microns) that are usually the most difficult products to sell. This holds the potential for Focus to create a high-margin business opportunity by providing customers with a finer grade, lower cost, value-added graphite product.

Battery manufacturers require a cost competitive alternative to current sources of synthetic and natural flake graphite. China produces the majority of the world’s purified SPG, using methods generally regarded as environmentally unsustainable.

Presentation of Data:

All Lac Knife flake graphite materials tested were purified, spheronized and sized for application in the anodes (negative electrodes) of Lithium-Ion batteries. The anodes for all samples tested consisted of 90% graphite, 7% PVDF binder and 3% carbon black and a copper coil current collector with a thickness of 20 microns. All cells were assembled and tested in a CR2016 coin cell configuration prepared with 1M LiPF6/EC/DMC electrolyte and lithium foil counter electrodes. The coin cells were then cycled between 0.003 and 1.5 volts. Formation was carried out with C/10 current density and cycling was carried out with the same voltage limits at C/10. To evaluate the cycling performance, half cells made with the lithium metal counter electrode were charged and discharged at a relatively low current density and cycled galvanostatically at a C/10 rate until the limit of the test was reached.

Focus is currently engaged in battery testing with more than 20 potential end-users and seven universities and government laboratories.

Focus has established a recent history of technological successes by designing processes leading to superior performing coated spherical graphite for use in battery anodes and high performing expanded graphite for use in Li-Ion battery cathodes.

The Company’s proprietary, low temperature process, developed by a Focus Graphite technical team headed by Dr. Doninger, is believed to be more efficient than very high temperature thermal purification and is suitable for the removal of specific types of impurities found in the Lac Knife graphite deposit.

The path from graphite product development to the battery manufacturers' testing labs is a lengthy, multi-step process.

Staged R&D testing is a prerequisite to the sale, or offtake, of any manufactured graphite for use in lithium-ion, alkaline and lead-acid batteries in the automobile, consumer, medical equipment, tools, hand-held industrial devices and aviation manufacturing industries or with military equipment suppliers.

Qualified Person

Dr. Joseph Doninger, Focus Graphite's Director of Technology and Manufacturing is the Qualified Person under National Instrument 43-101 - Standards of Disclosure for Mineral Projects - has reviewed and approved the technical content of this news release. Dr. Doninger is an internationally recognized graphite processing expert and himself, the inventor of a number of patents and an author of over 27 technical papers and presentations related to graphite processing and the use of graphite in energy storage systems. Dr. Doninger is a co-editor on the NATO Science Series book titled "New Carbon Based Materials for Electrochemical Energy Storage Systems". Dr. Doninger is also an Honorary Professor at the Department of Chemistry from the Kiev National University of Technologies and Design.

About Focus Graphite

Focus Graphite Inc. is an advanced exploration and mining company with an objective of producing graphite concentrate at its wholly owned Lac Knife flake graphite deposit located 27 km south of Fermont, Québec. In a second stage, to meet Quebec stakeholder interests of transformation within the province and to add shareholder value, Focus is evaluating the feasibility of producing value added graphite products including battery-grade spherical graphite.

Focus Graphite is a technology-oriented graphite mining development company with a vision for building long-term, sustainable shareholder value. Focus also holds a significant equity position in graphene applications developer Grafoid Inc.

For more information about Focus Graphite, please visit www.focusgraphite.com.